Extrusion is the process for manufacturing plastic sheets or sheeting.

“Sheet” and “sheeting” are generally differentiated by thickness – sheeting is up to 2.2 mm, sheet thicker than 2.2 mm.

The production principle is identical for both sheet and sheeting, with the exception of the packaging at the end of the line. Sheet is palletised while sheeting is wound on a bobbin.

The main steps are as follows:

- transfer of material pellets to feed chutes, dosing and mixing

- heating and kneading of the material using one or more extrusion screws

- shaping the mass of molten material in the die

- calendering

- cutting

- palletisation

Transferring material pellets to the feed chutes, dosing and mixing:

Material is generally transferred by a feed system, pellets being fed to the extrusion screw feed chutes.

Several types of materials are mixed there, together with various additives (such as colouring agents)

Heating and kneading of the material using one or more extrusion screws:

The material pellets fall by gravity into extruders comprising a heating sleeve and an endless screw (extrusion screw). Rotation of the screw draws the material along the sleeve where it is subjected to different actions, produced by the heating chambers and by kneading resulting from the variable profile of the threads and screw core. The material is successively “pumped”, heated, compressed, kneaded and decompressed (degassed).

Shaping the molten material in the die:

The molten material leaves the screw in the form of a cylinder which has to be converted into a sheet of material. This is done by the die. Various settings on this die allow a constant thickness and identical flowrate of material at all points to be achieved.

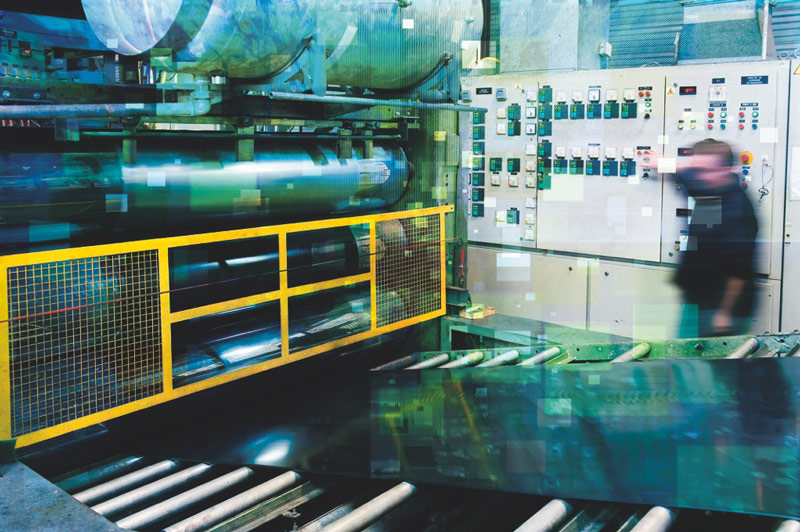

Calendering:

When it leaves the die, the sheet of material has not achieved the required accuracy. The calendering operation grades the thickness with a high degree of accuracy. The purpose of calendering is also to cool the material to a temperature at which it is solid.

Cutting:

The strip of material is cut widthways using knives or saws.

It is also cut lengthways using cutters or a saw.

Palletising:

When cut, the sheets are palletised.

Applications

Sheets produced by extrusion are used for cutting, thermoforming or fabrication.

Extruded materials

The majority of thermoplastics can be extruded. Examples include PE, PP, ABS, PS, PC and PVC.